|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||

GS1 Sunrise 2027 - Digital Link 2D Barcode Generator Barcode Printer Scanner Accessories |

|||||||||||||||||||||||||||||||||||||||||||||

|

More powerful desktop free barcoding software CNET Recommends: Best Free Barcode Generator Alternatives for Windows |

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

There are three versions of the software: |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Summary: 1. This software has a permanent free version and a full version. 2. The free version can meet the needs of most users. 3. You can test the functionality of the full version in the free version. 4. We recommend you download the free version first. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Download Now - Free Version Barcoding Software

Detail steps about how

to use this software

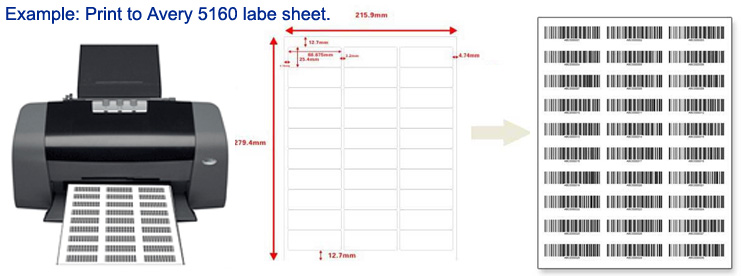

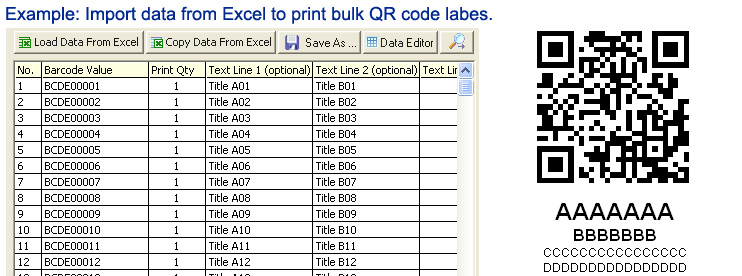

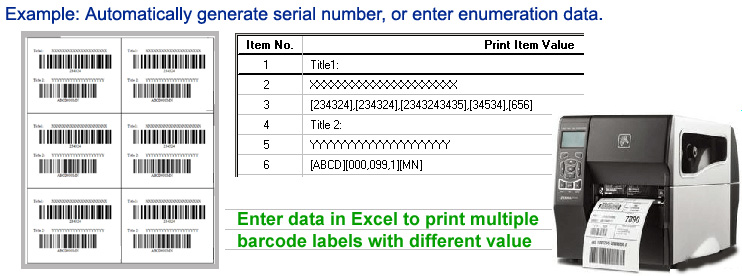

Desktop software can export a set of barcode images to a folder |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Barcode Technology - Code 128 (Barcode 128) Hide the description |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code-128 (Barcode 128) is a high-density linear barcode symbology. It is used for alphanumeric or numeric-only barcodes. It can encode all 128 characters of ASCII and, by use of an extension symbol (FNC4), the Latin-1 characters defined in ISO/IEC 8859-1.[citation needed]. It generally results in more compact barcodes compared to other methods like Code 39, especially when the texts contain mostly digits. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Valid characters: 0123456789!"#$%&''()*+,-./:;<=>?@[\]^_`{|} [Space]ABCDEFGHIJKLMNOPQRSTUVWXYZ abcdefghijklmnopqrstuvwxyz Control characters: ASCII 1-31,127 |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code 128 Auto can encode the complete ASCII-character set. It will switching in all 3 character sets of Code 128:

Code 128A: Includes upper case

letters and control characters. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code 128 is one of the many barcode formats currently in use. |

|||||||||||||||||||||||||||||||||||||||||||||

|

A Barcode is a method of representing data in a visual, machine-readable form. |

|||||||||||||||||||||||||||||||||||||||||||||

|

The barcode formats has two categories: |

|||||||||||||||||||||||||||||||||||||||||||||

|

One-dimensional (1D) --- Barcodes represented data by varying the widths and spacings of parallel lines. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Two-dimensional (2D) --- Using rectangles, dots, hexagons and other geometric patterns to represented data. |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

|

For the end user, Code 128 barcodes may be generated by either an outside application to create an image of the barcode, or by a font-based barcode solution. Either solution requires the use of an application or an application add in to calculate the check digit and create the barcode. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Check digit:

The check digit is a weighted

modulo-103 checksum. It is

calculated by summing the start

code 'value' to the products of

each symbol's 'value' multiplied

by its position in the barcode

string. The start symbol and

first encoded symbol are in

position 1. The sum of the

products is then reduced modulo

103. The remainder is then

converted back to one of the 103

non-delimiter symbols (following

the instructions given below)

and appended to the barcode,

immediately before the stop

symbol.

==================================================================================

---------------------------------------------------------------------------------------------

=================================================================================== |

|||||||||||||||||||||||||||||||||||||||||||||

|

Barcode length optimization: Code set C (Code 128C) uses one code symbol to represent two digits, so when the text contains just digits it will generally result in shorter barcodes. However, when the string contains only a few digits or it's mixed with non-digit character, it does not always produce a more compact code than code sets A or B. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Human Readable: Most barcodes display their corresponding values below them, which makes it possible to human read and manually enter the barcode values into the equivalent system when the barcode label is worn out and cannot be read by the barcode scanner. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Advantages: If you want to reduce costs and save time, using barcodes is a good choice. Whether you are a company or a non-commercial organization, to improve efficiency and reduce overhead, barcodes are a valuable and viable option, which is economical and reliable. Using a barcode system can make the working process simple and easy, so it can reduces the employee training time. It only takes a few minutes to master the barcode scanner to collecting data, employees no need to familiar with the entire inventory or pricing process. This also reduces the cost of employee training. The bar code design and printing cost are low. Generally speaking, no matter how they are used or where they are posted, the cost is not high. They can be customized economically, in a variety of finishes and materials. The barcode system is very versatile, it can be used for any necessary data collection. This may include pricing or inventory information or management information service system. In addition, because barcodes can be affixed to almost any surface, they can be used not only to track the product itself, but also to track the production process, shipments and equipments. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Frequently Asked Questions About Code 128 Barcode |

|||||||||||||||||||||||||||||||||||||||||||||

|

What is the origin and development process of Code 128 barcode? |

|||||||||||||||||||||||||||||||||||||||||||||

|

The Code 128 barcode was developed by COMPUTER IDENTICS in 1981. It is a variable-length, continuous alphanumeric barcode. It can encode all 128 ASCII characters. Code 128 barcode is a barcode system that can encode alphanumeric or numeric data. They are widely used in manufacturing and distribution industries to track and manage products, inventory, assets, orders, and shipments. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What are the benefits of using Code 128 barcodes? |

|||||||||||||||||||||||||||||||||||||||||||||

|

It can encode all 128 ASCII characters, including numbers, letters, symbols and control characters, so it can represent all characters on the computer keyboard. It enables high-density and efficient data representation through multi-level encoding and can be used for automatic identification in any management system. It is compatible with the EAN/UCC system and is used to represent the information of the storage and transportation unit or logistics unit of the commodity. In this case, it is called GS1-128. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Who developed the Code 128 barcode standard? |

|||||||||||||||||||||||||||||||||||||||||||||

|

The Code 128 barcode standard was developed by Computer Identics Corporation (USA) in 1981. It can represent all 128 ASCII code characters and is suitable for convenient application on computers. The purpose of formulating this standard is to improve the coding efficiency and reliability of barcodes. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What is the structure of the Code 128 barcode? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code 128 barcode consists of a blank area, a start mark, a data area, a check character and a terminator. It has three subsets, namely A, B and C, which can represent different character sets. It can also achieve multi-level encoding through the selection of starting characters, code set characters, and conversion characters. Code128 is a high-density barcode. By using three versions of character sets (A, B, C) and selection of start characters, code set characters, and conversion characters, the most optimal barcode can be selected according to different data types and lengths. Appropriate encoding method. This can reduce the length of the barcode and improve coding efficiency. In addition, Code128 also uses check characters and terminators, which can increase the reliability of barcodes and prevent misreading or missed reading. |

|||||||||||||||||||||||||||||||||||||||||||||

|

How many types of Code 128 barcodes are there? |

|||||||||||||||||||||||||||||||||||||||||||||

|

There are three subsets of Code 128 barcodes, namely A code, B code and C code. Code 128 barcodes can represent 128 ASCII values by switching different subsets, and there is no theoretical limit to the code length. Code 128 A code: can encode uppercase letters and control characters (such as TAB, CR/LF, etc.), but cannot encode lowercase letters. Code 128 B code: can encode upper and lower case letters, but cannot encode control characters. Code 128 C code: can only encode numbers 0-9, and each two numbers are represented by a barcode symbol. It is the most compact code set |

|||||||||||||||||||||||||||||||||||||||||||||

|

Why use check characters and terminators on barcodes? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Because both check characters and terminators can improve the reliability of barcodes and prevent misreading or missed reading. The check character is a character obtained by calculating the content of the data area according to a certain algorithm after the barcode data area. It helps the scanning device check whether the barcode has been read correctly. If the checksum does not match the calculated result, the barcode is incorrect. The terminator is at the end of the barcode and is used to indicate the end of the barcode. It can help the scanning device determine the boundaries of the barcode and prevent irrelevant content from being scanned. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What is the difference between Code 128 barcode and GS1-128 barcode? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Different application scopes: Code 128 barcodes can be used for automatic identification in any management system, while GS1-128 barcodes must be used in the GS1 system to represent information on storage and transportation units or logistics units of goods. The components are different: Code 128 barcode consists of a blank area, a start character, a data area, a check character, a terminator, and a blank area. The GS1-128 barcode adds an application identifier (AI) in front of the data area to indicate different types of data. Different reading methods: Any reader that can read Code 128 barcodes can read the data of GS1-128 barcodes, but the application identifier needs to be parsed to get the correct information. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What is the difference between the GS1-128 barcode and the EAN-128 barcode? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Different names: GS1-128 is the new name for the EAN-128 barcode, used since 2009 to emphasize that it is a standard of the GS1 organization. The structure is different: GS1-128 barcode adds an FNC1 character before each application identifier (AI) to distinguish different data segments. Different contents: GS1-128 barcode can represent more data types, such as batch number, expiration date, weight, etc., while EAN-128 barcode can only represent product number. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What is the difference between Code 128 barcode and QR Code? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code 128 barcode is a one-dimensional barcode, and QR Code is a two-dimensional barcode. One-dimensional barcodes can only represent information in the horizontal direction, while two-dimensional barcodes can represent information in both horizontal and vertical directions, so the information capacity of two-dimensional barcodes is larger. Code 128 barcode can represent a total of 128 characters (including numbers, letters, symbols) from ASCII 0 to ASCII 127. There is no theoretical limit to the code length, but it is limited by the printing width of the printer and the scanning width of the scanner. What it can contain The number of characters generally cannot exceed 50. QR Code can represent numbers, letters, Chinese characters and other characters, and the maximum code length is 7089 numbers or 2953 Chinese characters. The Code 128 barcode requires a dedicated scanning device to be recognized, while the QR Code can be scanned and recognized using a smartphone or other device. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Will Code 128 barcode be replaced by QR Code? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Won't. Because Code 128 barcode and QR Code each have their own advantages and disadvantages, they are suitable for different occasions and needs. Generally speaking, Code 128 barcodes are more suitable for representing simple numeric or alphabetical information, such as logistics order numbers, product numbers, etc., while QR Codes are more suitable for representing complex text or image information, such as website addresses, business cards, coupons, etc. The advantages of Code 128 barcodes are small footprint, fast scanning speed and high reliability. However, its disadvantage is that its information capacity is limited and it cannot represent characters such as Chinese characters. It requires special scanning equipment to recognize it. The advantage of QR Code is that it has a large information capacity, can represent a variety of characters and images, can be scanned and recognized with devices such as smartphones, has error correction capabilities, and can recover partially damaged information. However, its disadvantages are that it takes up a lot of space, has a slow scanning speed, and is susceptible to interference. Therefore, Code 128 barcode and QR Code are not completely substitutes, but complementary relationships. Users should choose the appropriate barcode type based on different application scenarios and needs. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What are the advantages and disadvantages of Code 128 barcodes? |

|||||||||||||||||||||||||||||||||||||||||||||

|

The Code 128 barcode is a high-density one-dimensional barcode that can encode 128 ASCII characters. It has the following advantages and disadvantages: Advantage: Allows bidirectional scanning processing, improving recognition efficiency. The length of the barcode can be adjusted freely, and up to 232 characters can be encoded. You can choose from three different encoding types: A, B, and C, and choose the most appropriate method according to the data type and length. Shortcoming: There are high requirements for print quality and scanning equipment, otherwise it is easy to make mistakes. A check code needs to be added, which increases the complexity of the barcode. Special start and end characters need to be used, which takes up a certain amount of space. |

|||||||||||||||||||||||||||||||||||||||||||||

|

What are the main application scenarios of Code 128 barcodes? |

|||||||||||||||||||||||||||||||||||||||||||||

|

Code 128 barcodes are widely used in internal corporate management, production processes, and logistics control systems. It has many application scenarios, mainly in industries such as transportation, logistics, clothing, food, pharmaceuticals, and medical equipment. t can encode numbers and letters, as well as some special symbols and control characters. There is also a subset of the Code 128 barcode called GS1-128, which is a product identification code used for supply chain management. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Some application examples of Code 128 barcodes. |

|||||||||||||||||||||||||||||||||||||||||||||

|

Internal supply chain: Internal management of enterprises, production processes, logistics control systems, ordering and distribution codes. Code 128 barcodes can store various information, such as item number, batch, quantity, weight, date, etc. This information can be used for tracking, sorting, inventory, quality control, etc., to improve the efficiency and accuracy of the company's internal supply chain management. Production line process: Code 128 barcodes can be used in factory production line process management to monitor production, order fulfillment and distribution processes in real time, improving production efficiency and quality. Code 128 barcodes can identify product numbers, batches, specifications, quantities, dates and other information to facilitate traceability, inspection, statistics and other operations during the production process. Code 128 barcodes can also be integrated with other systems, such as ERP, MES, WMS, etc., to achieve automatic collection and transmission of data. By affixing Code 128 barcodes to products or parts, you can track and monitor all aspects of the production process, improving production efficiency and quality. By affixing Code 128 barcodes to packaging or shipping boxes, automatic identification and recording of logistics information such as entry and exit, distribution, and inventory can be achieved, improving the accuracy and efficiency of logistics management, helping to transport products quickly, and ensuring that they are shipped correctly. Deliver the right product to the right customer at the right time to meet customer demand and reduce inventory costs. By affixing Code 128 barcodes to workers or equipment, automatic collection and analysis of personnel or equipment attendance, performance, maintenance and other information can be achieved, improving the level of human resources and equipment management, and reducing manual steps to reduce labor costs. Transportation and Logistics: Used for ordering and distribution codes, product warehousing management, logistics control systems, ticket sequence numbers in international aviation systems. Code 128 barcode is used for ordering and distribution in the logistics and transportation industry. They can encode Serial Shipping Container Codes (SSCC) to identify and track containers and pallets in the supply chain. They can also encode other information such as best before dates and batch numbers. Code 128 barcodes can be scanned by WMS to increase warehouse efficiency. Logistics tracking: Code 128 barcodes are widely used in logistics tracking. They can be used to identify goods, orders, prices, inventory and other information. A subset of Code 128 barcodes is GS1-128, an international standard used to identify containers and pallets at levels in the supply chain. You can use a Code 128 barcode scanner to read this information quickly and accurately. |

|||||||||||||||||||||||||||||||||||||||||||||

|

COPYRIGHT (C) EasierSoft Ltd. 2005-2024 cs@easiersoft.com |

|||||||||||||||||||||||||||||||||||||||||||||

| Privacy Policy |